RUBBERINC TINCURE

RUBBERINC PLATINUM CURE

What is Tin-Cure Silicone? | Rubber Inc Guide

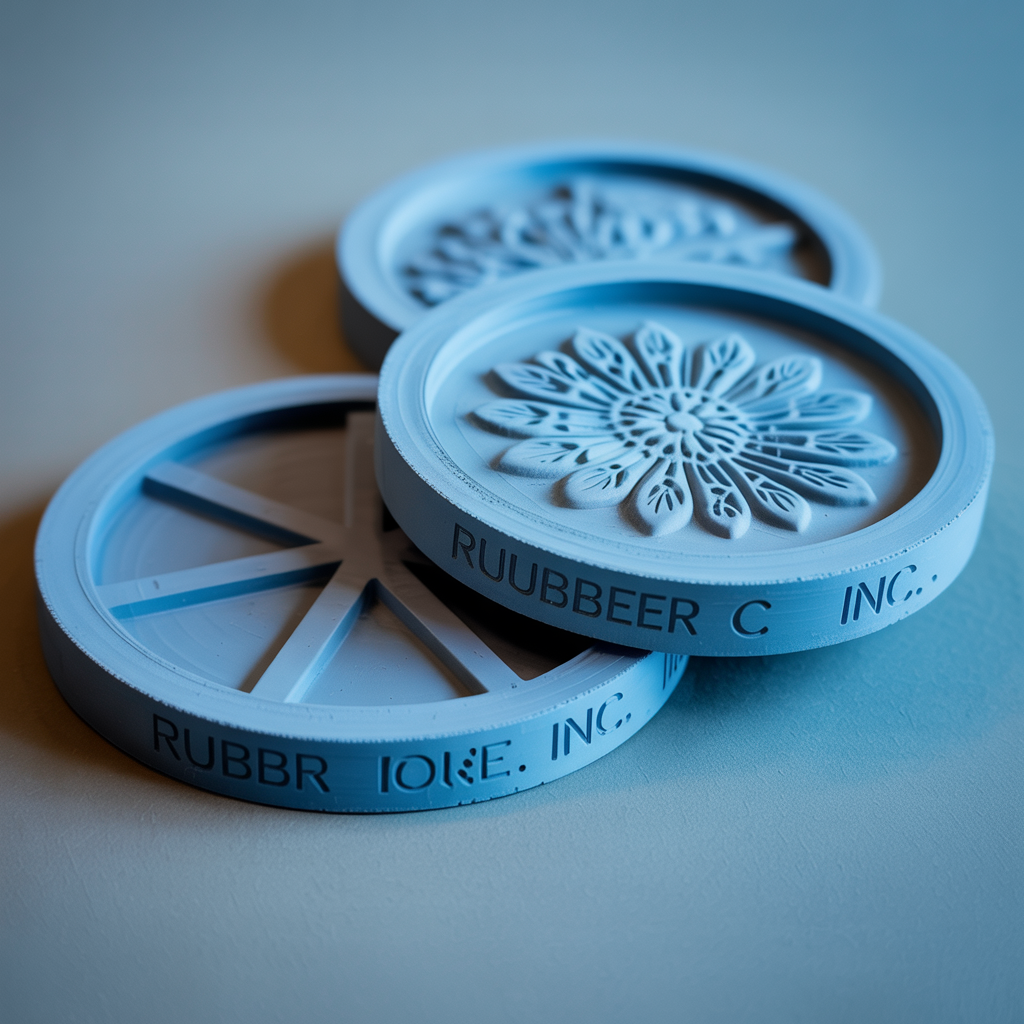

Tin-cure silicone, also known as condensation-cure silicone rubber, is a high-performance, versatile molding material widely used in art, architecture, manufacturing, and DIY applications. At Rubber Inc, we offer premium tin-cure silicone products engineered to deliver precise detail replication, fast curing times, and professional-grade results across various industries.

Understanding Tin-Cure Silicone Rubber

Tin-cure silicone is a two-part RTV (Room Temperature Vulcanizing) silicone rubber that cures when a base and a catalyst (usually containing tin compounds) are mixed. This process produces flexible, durable molds ideal for gypsum, wax, concrete, resin, and low-melt metals.

Key Features of Rubber Inc Tin-Cure Silicone

✅ High Flexibility: Ideal for capturing fine details and complex textures

✅ Fast Curing: Available in quick-setting versions for faster production

✅ Strong Tear Resistance: Ensures molds last through repeated use

✅ User-Friendly Ratios: 1:1 or 100:5 mix ratios available

✅ Room Temperature Curing: No special equipment needed

✅ Color Variants: Signature blue-toned finish for visual quality control

✅ Available Sizes: 20kg, 5kg, 1kg buckets — perfect for any scale of production

Applications of Tin-Cure Silicone Rubber

Rubber Inc Tin-Cure silicone is widely used across multiple industries and projects:

Interior Decor Moldings

Gypsum Art Panels

Soap and Candle Molds

Resin Casting

Architectural Details

Prototype Models

Sculpture and Figurine Molds

Industrial Gasket Templates

Silicone Skins for FX (non-skin-safe projects)

What is Platinum-Cure Silicone? | Rubber Inc Professional Guide

Platinum-cure silicone, also called addition-cure silicone rubber, is a high-precision, high-performance elastomer known for its exceptional purity, durability, and safety. At Rubber Inc, our platinum-cure silicone products are engineered for industries that demand medical-grade, food-grade, or high-detail molding — making them perfect for everything from art and industrial prototyping to culinary molds and medical casting.

Understanding Platinum-Cure Silicone Rubber

Platinum-cure silicone is a two-part RTV (Room Temperature Vulcanizing) system that cures through an addition reaction using a platinum catalyst. This advanced chemistry delivers longer shelf life, faster curing times, and superior mechanical strength compared to tin-cure silicone.

It is ideal for applications where non-toxicity, chemical resistance, and dimensional stability are essential.

Key Features of Rubber Inc Platinum-Cure Silicone

🧪 Ultra-Pure Formulation: Food-safe and skin-safe for sensitive applications

🧊 High Dimensional Stability: Minimal shrinkage even after multiple uses

🧼 Non-toxic & Odorless: Certified for contact with food, body, and medical items

⚙️ Durable & Tear-Resistant: Built for high-volume mold cycles

🌡️ Temperature Resistant: Withstands high and low temperatures

🔄 Reusable & Flexible: Keeps shape and elasticity over time

📦 Available Sizes: 1kg and 5kg (Part A + B) systems

🎨 Visual Clarity: Often translucent or white for easy inspection during mixing and casting

Applications of Platinum-Cure Silicone Rubber

Rubber Inc’s platinum-cure silicones are used in some of the most demanding and creative industries, including:

🍩 Food Molds (Chocolate, Ice, Candy, Baking)

🎭 Prosthetics and Special FX Masks

👶 Baby Products & Skincare Tool Molds

🧼 Soap & Cosmetic Molds

🧬 Medical Devices and Lab Testing Accessories

🔧 Industrial Prototyping & Precision Tooling

🛋️ Luxury Decor Casting (Clear & Detailed Resin)

📱 Wearable Tech Skins and Silicone Shells